The Problem We Solve

The United States is facing a major shortage of lithium and other critical minerals essential to clean energy and national defense. Lithium powers electric vehicles, energy storage systems, and advanced military technologies, yet the nation supplies only about one percent of the world’s lithium materials. This heavy dependence on foreign sources, especially China, leaves the U.S. vulnerable to supply disruptions and geopolitical risk.

At the same time, American industries generate millions of gallons of brine waste every day. Managing this waste is costly, environmentally risky, and highly regulated, even though it often contains lithium and other valuable minerals. BluCore addresses both challenges with its patented liquid to liquid extraction technology, enabling existing facilities to recover lithium directly from their own wastewater. This process saves water and energy, lowers disposal costs, and transforms waste into a secure domestic supply of critical minerals that strengthens America’s clean energy independence.

How Our Technology Works

BluCore’s patented process uses a breakthrough liquid to liquid extraction system that recovers lithium and other valuable minerals directly from wastewater. The technology is simple to adopt, easy to maintain, and creates a new revenue source for facilities that already handle brine.

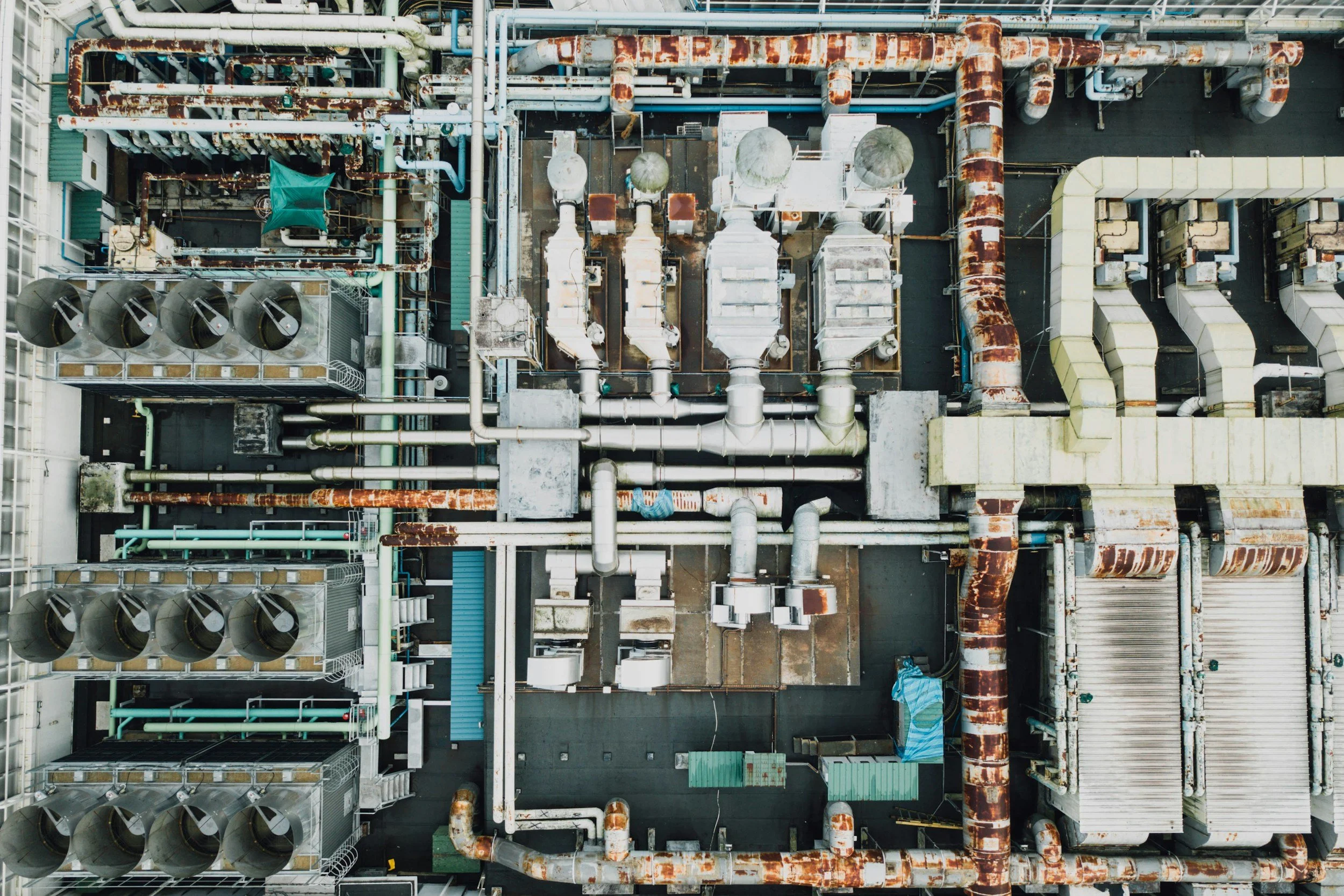

Step 1: Brine Waste System Integration

We do not build new mining sites or disrupt existing operations. Instead, BluCore installs modular extraction systems directly into facilities such as desalination plants, geothermal sites, and oil and gas operations. These systems connect to existing brine streams, capturing minerals that would otherwise be discarded. The result is a seamless upgrade that adds value without adding complexity.

Step 2: Selective Lithium Extraction

Our proprietary organic solvent mixes with the brine wastewater and targets lithium ions with precision, even when other minerals are present. This selectivity allows for consistent and efficient extraction from nearly any brine source, turning everyday waste into a renewable resource.

Step 3: Back Extraction and Recovery

Captured lithium is then separated from BluCore’s proprietary organic solvent through a closed loop back extraction process. The lithium is then refined into a pure solution ready for downstream use, while the solvent is recycled continuously, minimizing waste and cost.

Step 4: Storage, Sale, and Distribution

Recovered minerals are stored and prepared for commercial sale. Each facility has the option to ship its materials directly to trusted buyers and processors, or BluCore can handle collection and distribution on their behalf. This service provides consistent quality control, streamlined logistics, and full traceability from recovery to resale.

By simplifying both production and distribution, BluCore connects wastewater management directly to the clean energy economy, allowing facilities to benefit without the burden of managing new supply chain operations.

The system is fast to install, low maintenance, and designed to integrate with existing infrastructure. BluCore gives plant owners a practical way to reduce waste, lower environmental impact, and generate new revenue from the resources they already manage every day.